A Comprehensive Overview to the Different Sorts Of Industrial Scales Available Today

The commercial landscape is replete with varied weighing demands, necessitating a myriad of scale kinds. From heavy-duty platform scales to precision-based checking scales, each variant provides to unique needs, using unequaled precision and efficiency. Agricultural scales.

Recognizing the Relevance of Accurate Weighing in Industries

In the huge world of industrial operations, the relevance of precise considering is frequently taken too lightly. Yet, it plays a pivotal function in preserving top quality, guaranteeing safety, and enhancing performance. Industries such as drugs, food and beverage, or logistics count heavily on precise weight measurements.

Errors in considering can bring about tragic effects. As an example, inaccurate weight data can compromise product high quality, causing non-compliance penalties or costly recalls. In drugs, errors can risk people' lives. In logistics, it can incur additional delivery costs.

Precise considering ensures ideal usage of resources, reducing waste and hence, shielding the atmosphere. It likewise improves performance, as workers invest less time dealing with errors.

Accuracy in evaluating is not just concerning having advanced scales. It additionally involves normal calibration and maintenance of these ranges, in addition to training employees to utilize them correctly. Thus, comprehending the value of exact weighing is basic to industrial success.

A Review of the Different Kinds Of Industrial Scales

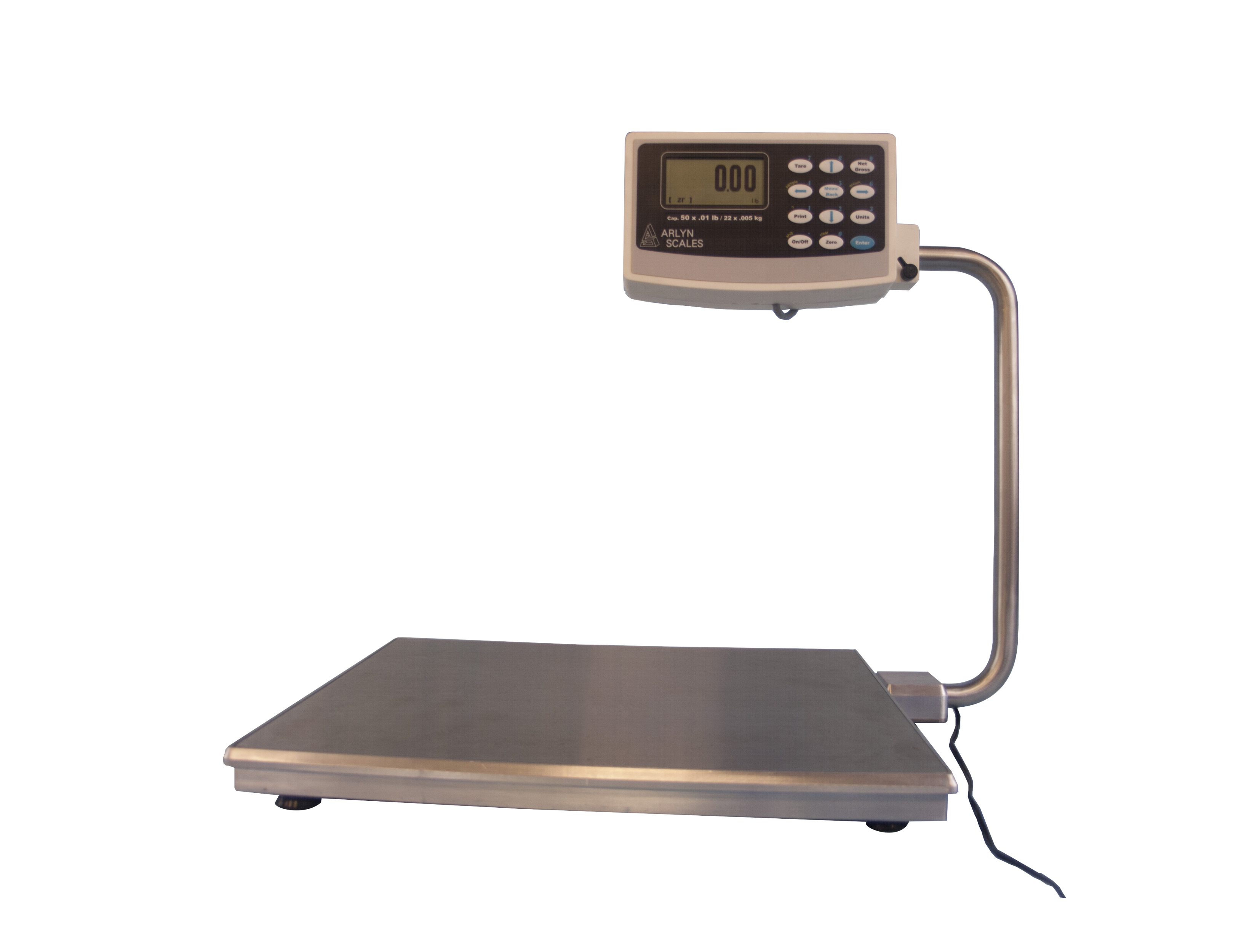

While there is a substantial variety of commercial scales offered on the market, each kind serves certain requirements and applications. Amongst these are platform ranges, which are typically utilized for sturdy applications because of their durable build and high weight capability. Bench ranges, on the other hand, are preferable for lighter loads and are usually utilized in laboratories and producing setups.

Another range is the crane range, made for training and evaluating hefty objects in industrial environments. Flooring scales, at the same time, rest straight on the ground and are utilized for evaluating big things that can be relocated on and off the scale using a pallet jack.

Counting scales are one more kind, typically made use of in inventory monitoring to count large quantities of items promptly. There are equilibrium ranges, offering exact dimensions and normally utilized in clinical and pharmaceutical applications. Each type has its very own unique features and benefits, made to fulfill a variety of industry needs.

When Selecting an Industrial Scale, secret Considerations.

Selecting the suitable industrial scale for a particular procedure requires careful thought and factor to consider. One blog here have to review the details requirements of their company, including the weight series of things to be determined, the environment in which the scale will certainly run, and the precision needed.

The weight array requirement is essential as industrial ranges differ in their maximum abilities. A scale made use of for determining big deliveries may check out here not need as much accuracy as one used for specific chemical measurements.

In-depth Examination of the Leading Industrial Scale Brands

Offered the wide variety of options offered out there, evaluating leading industrial range brands can be a difficult job. Some brand names have set themselves apart via quality, sturdiness, and progressed features.

One such brand is Mettler Toledo, a global leader renowned for its accuracy and technical development. Their scales range from small bench scales to sturdy vehicle ranges, guaranteeing a service for each industrial requirement.

A&D Considering is another top brand, preferred for its versatility in applications and items, while Fairbanks has earned acknowledgment for its reliable and durable scales, specifically in heavy-duty applications. Agricultural scales.

Rice Lake Weighing Equipments, on the other hand, provides a wide array of ranges, understood for their premium building and accuracy.

Each of these brand names offers one-of-a-kind advantages, making the selection based on particular market needs and budget plans.

The Future of Industrial Considering: Technological Innovations and Trends

As the world comes to be progressively electronic, the future of commercial considering is established to evolve with interesting technological improvements and trends. The assimilation of synthetic knowledge and Internet of Things (IoT) are at the forefront of these innovations, promising to transform the industrial evaluating landscape.

AI-powered wise navigate to these guys ranges, for circumstances, have the ability to self-calibrate and execute error checks, lowering downtime and improving productivity. These scales can also examine and analyze information, providing beneficial understandings that can drive process improvements.

On the other hand, IoT modern technology is allowing remote surveillance of commercial ranges. This not just decreases the need for hand-operated examinations yet also enables real-time data collection and evaluation. This can bring about a lot more reliable stock management and predictive maintenance.

With these modern technologies, the future of industrial evaluating looks readied to be more precise, efficient, and automated, providing sectors with crucial data in real-time and boosting general efficiency.

Conclusion

From heavy-duty system scales to careful checking scales, each kind provides to particular evaluating demands. As innovation advancements, commercial ranges continue to progress, promising more accuracy and convenience.

The industrial landscape is loaded with varied weighing needs, demanding a myriad of range types. From durable platform ranges to precision-based checking ranges, each alternative caters to one-of-a-kind needs, offering unequaled precision and efficiency.While there is a considerable range of industrial scales available in the market, each kind serves specific requirements and applications.The weight array requirement is crucial as industrial ranges vary in their optimum capacities. From heavy-duty system scales to precise counting ranges, each kind caters to details considering needs.

Comments on “Industrial Scales for Consistency: Enhancing Accuracy in Production Lines”